One of the biggest frustrations that a customer has with any business is order delay. On-time fulfillment is key to customer satisfaction. Delays can significantly damage the reputation of a business, so correcting the lagging areas in your business process should be a priority.

An effective way to fix these delays is to shorten the lead time. Doing so will translate to improved productivity and efficiency, less frustration for the customer and more.

What is Lead Time?

Lead time refers to the amount of time spent between receiving the order of the customer to the service delivery or final product. When you look at lead time from a supply chain management perspective, this describes the time taken to obtain supplies once you place an order.

Businesses can uncover inefficiencies in this particular when they compare the results against the established benchmarks.

Differentiating Lead Time and Cycle Time

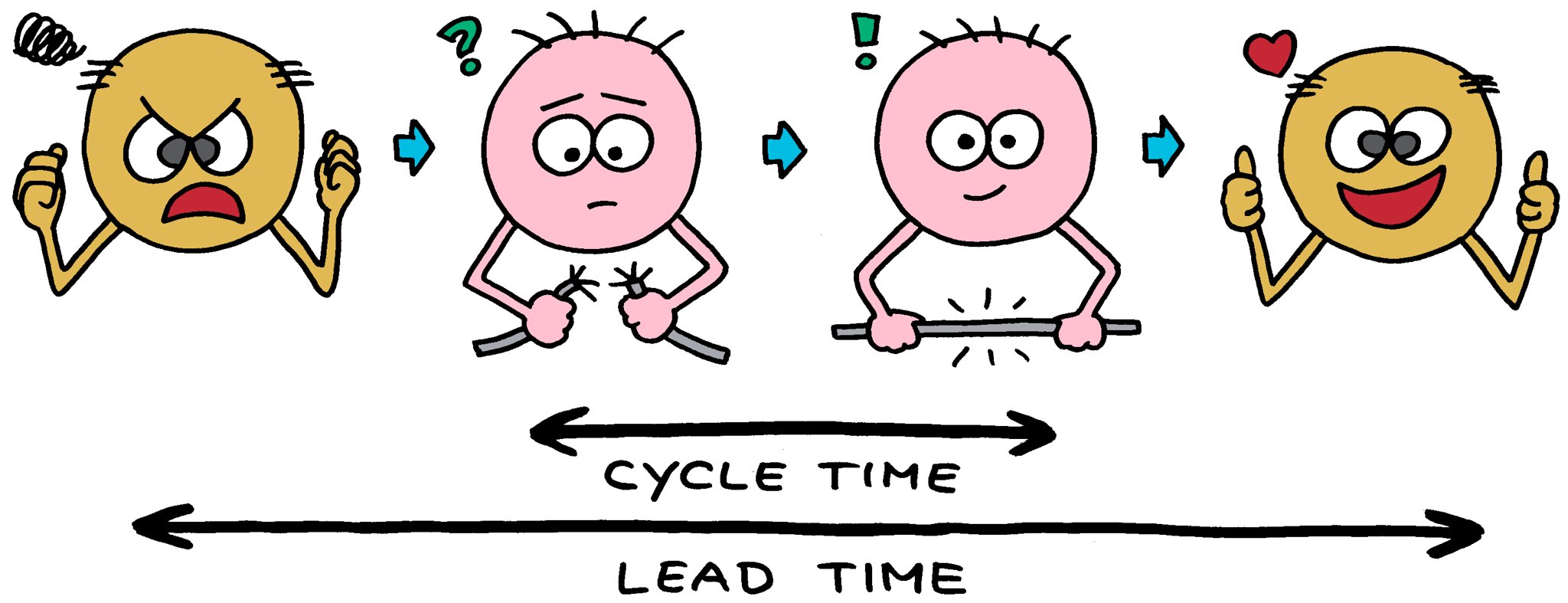

Lead time and cycle time are two crucial metrics in Lean and process improvement. Many people, however, don’t fully understand their differences. Some even use these terms interchangeably. This can result in poor decisions in process improvement, as well as confusion in understanding the true issues in a process.

Let’s first define cycle time. This term refers to the amount of time taken to complete a process cycle from the beginning until its conclusion. Although the word “process” usually describes the production process in manufacturing, the term can be any repetitive activity, such as answering customer phone calls.

Another definition of cycle time is the amount of time that a team works on a product until it is ready for customer delivery. If a customer orders food online, for instance, the cycle time in this situation would refer to the time taken to prepare the ordered meal.

So, here are a few facts that distinguish lead time from cycle time:

- Lead time helps businesses predict customer wait time. On the other hand, cycle time helps companies estimate the production rate.

- Lead time takes into account the entire production process, from getting the order to delivering the final product. Cycle time, in contrast, only considers a segment of the whole production process.

- Businesses aim for lower a lead time to achieve better customer satisfaction. On the other hand, companies aim for a shorter cycle time to cater to higher customer demands.

How to Calculate Lead Time

The formula for lead time in order management is order delivery time minus order received time. Here’s an example: let’s say the customer orders a single pizza over the phone at 3:15 PM and receives the food at 4:00 PM. The lead time in this scenario is 45 minutes.

Determining the lead time in supply chain and inventory management, however, is a little different. This metric is the sum of the supply delay (the amount of time a shipment takes to reach your inventory) and the reordering delay (the amount of time taken by your supplier to accept, process and start executing your purchase order).

Factors That Affect Lead Time

Companies looking to bring down manufacturing or production lead time will need a solid understanding of the factors affecting this metric.

A few of the things that can impact lead time are the following:

Inventory Control

Poor inventory management will adversely affect your company’s lead time. Getting a handle on inventory control will make sure that you know exactly what and how much stock your business has. This guarantees that all crucial parts are available for manufacturing runs.

Stockouts

Out-of-stock events are disastrous for companies, as these make goods production impossible. After all, you can’t make products without the necessary components and inventory stock. Frequent stockouts can result in extended lead time, customer dissatisfaction and lost sales opportunities.

Shipping Times

Delays in shipping can be difficult to control. Various factors affect shipping, including human error caused by burnout, natural disasters and raw material shortage. Managing shipping times is crucial for a business, as this can minimize the risk of order fulfillment delays.

Production Processes

Unnecessary or redundant processes in production or manufacturing can affect lead time. Building every part of a finished assembly, for instance, may take longer to finish each order. This cuts down production output and reduces the return on investment. The solution in this scenario would be to perform process optimization.

Why Reduce Lead Time

Minimizing lead time is instrumental to the success of a company. Your business can enjoy the following business when you focus on reducing this metric:

Higher Revenue

Lowering the lead time increases performance, which bumps up your overall revenue. Reliability brings in more customers to your business, boosting the output of products and the influx of more income.

When your lead time is low, you can raise your prices without worrying about a dip in sales. Customers are more willing to shell out cash for better service, and fast delivery of products or services is a major plus.

Improved Reputation

Customers expect to receive their ordered product or service as scheduled. Lengthy lead time can affect delivery — and this can reflect poorly on the business. When you address your production lead time, you can meet customer expectations. What’s more, your customers are likely to recommend your company to friends and family, which boosts your reputation as a reliable business.

Increased Production Efficiency

When you employ strategies to minimize lead time, you allow your factory or facility to run more smoothly. This translates to other positive effects, such as reduced labor and less waste.

How to Cut Down Lead Time

Now that you’re aware of the advantages of lead time reduction, the next step is to get that metric down to an acceptable level. Here are a few strategies that you can implement in your business:

Come up with a Lead Time Contract for All Your Suppliers

Any supplier can step forward and make bold claims about their awesome lead time. Many, however, won’t live up to the hype and fail to meet your business expectations.

When drafting a contract with a supplier, make sure that it contains terms and expectations on lead time. You want the supplier you’ll be working with to legally agree to the preset lead time.

The lead time contract should contain the following elements:

- Lead time for every specific stock or order

- Penalty for damaged goods during transportation

- Penalty for late and delayed shipments

- A timely notice of inventory discontinuations, stock shortages and price changes

Note: some suppliers may hesitate and feel uneasy about signing that document — and that’s a good thing. This means that they will be more realistic in what they can bring to the table. They’ll also likely push themselves to meet your company’s agreed-upon lead time.

Automate Your Inventory Management

Calculating lead times, producing sales reports and forecasting demand are easier to accomplish when you’re not wasting time manually writing purchase orders and entering data. By installing inventory management software, you can automate workflows on stocktaking, help balance your working capital and streamline your supply chain management.

Use Domestic Suppliers Where Possible

You can bring down your lead time significantly when you switch from international to domestic. If you’re going to get your supplies locally, make sure you look at the cost of the goods relative to the reduced lead time. This way, you’ll know if the shift will benefit your inventory management, supply chain and ultimately your customers.

Sweeten the Deal by Incentivizing Suppliers

If your supplier is giving a lead time that you’d like to reduce, make it worth their while. You could, for instance, provide bonuses for early and on-time deliveries.

Boost the Frequency of Your Orders

Some businesses choose to place orders in bulk every few weeks. This strategy gives them plenty of stock in their warehouse.

Bulk ordering, however, has a downside. If your business doesn’t sell or use your ordered goods in a timely fashion, your inventory may become obsolete. This means that you have to discard those goods or lower your selling prices. You’ll be at a loss either way.

Rather than purchase your goods in bulk, order small amounts more often. Base the frequency of your orders on realistic forecasts and accurate sales data. This helps boost your inventory turnover rate and lower your carrying costs.

Lead time is a critical metric for any company. Work on reducing this metric, so you can boost productivity and efficiency in your operational workflows, as well as deliver what your customers ordered on or ahead of schedule.